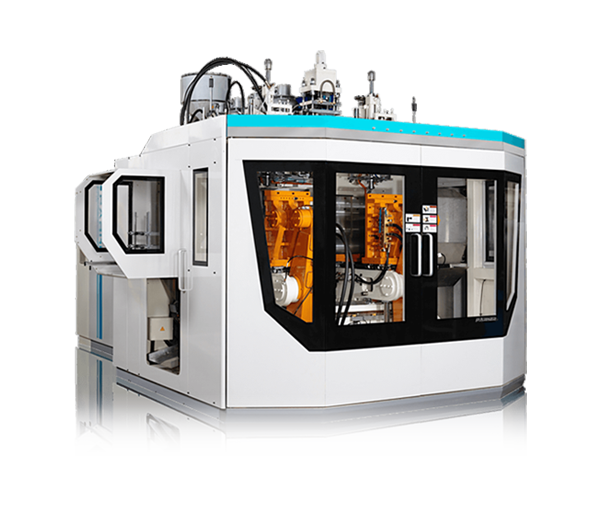

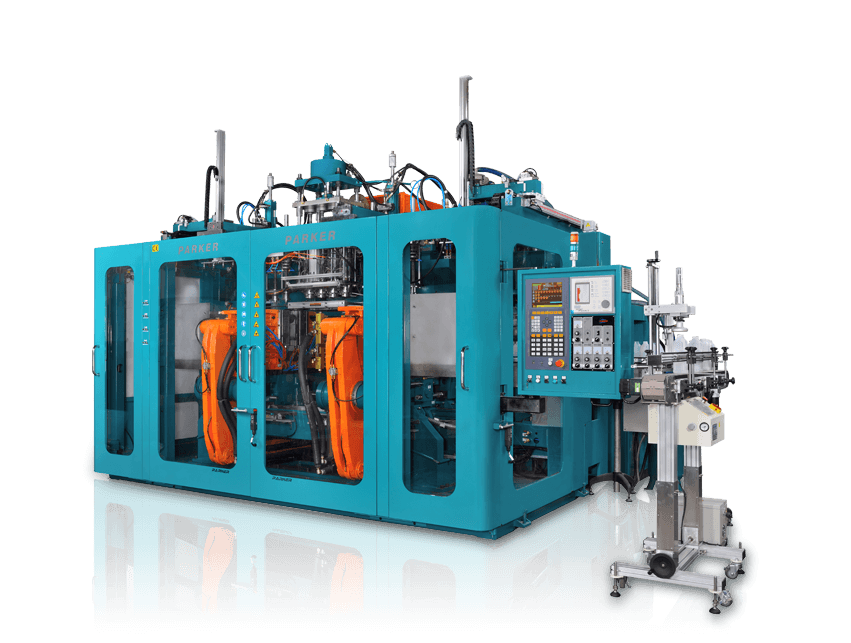

Double Station Blow Molding Machine

PK-CTS/CTD/CT3/CT4/CT8

- Double Station

- Single/Double/Triple/Quadruple..8 Head

- Production Volume:2ml~35L

- Multi layers: Co-Extrusion 1-6 Layers

- Multi cavities: 1~8 cavities

- Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material

- Special function:View Stripe

- Clampoing system:Toggle/3 tie bar/4 Tie Bar

- Driven Model: Hybrid servo motor drive system/ High performace hydraluic power saving system/Close loop proportional valve

- Support Parison controller/Auto Deflasing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML

Features & Application

Features

- HMI Touch Screen, Incorporating with PLC system (Optional Siemens/B&R Control) for easy maintenance.

- Blowing Unit/ Die Head movement for changing mold easily, as option.

- Built with safety devices to provide maximum protection for the machine operator.

- High plasticizing capacity extrusion screw is designed to handle material variations.

- Plasticizing screw and barrel is precision machined from special nitrogen treated steel.

- Water cooling technology controls feed zone temperature.

- Chiller circulated hydraulically controlled blow-pin.

- The twin station configuration allows for continuous blow molding. This eliminates down time and upgrades production.

- This series can operate with a selected single station.

- When requiring both functions in a single machine, purchase the machine for PVC application and order the additional parts (screw and die head ) for conversion to PE application.

Application

Dairy

Jerry Can

Cosmetic / Personal care

Edible Oil

Toys

Lub-oil Containers

Household Chemical

Household Chemical

Specification

| MODEL | UNIT |

PK45T

|

PK55T

|

PK65T

|

PK75T

|

PK90T

|

PK100T

|

PK110T

|

PK120T

|

||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material To Be Used | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP(Toggle) | PE/PP(Toggle) | PE/PP(Toggle) | |||||||||||||||||||||||||

| PRODUCT | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | TS | TD | T3 | T4 | |

| Product Volume (Min/Max) | cc | 100-500 | 50-200 | 30-100 | 5-50 | 300-1L | 100-500 | 50-200 | 30-100 | 500-2L | 300-1L | 100-500 | 50-200 | 2L-5L | 500-2L | 300-1L | 100-500 | 4L-10L | 1L-3L | 500-2L | 300-1L | 10L-25L | 2L-5L | 1L-3L | 500-2L | 10L-25L | 2L-5L | 1L-3L | 500-2L | 10L-30L | 2L-5L | 1L-3L | 500-2L |

| Product Dia. (Min/Max) | mm | 20-90 | 10-80 | 10-65 | 10-30 | 20-100 | 20-80 | 10-65 | 10-60 | 30-130 | 30-100 | 10-80 | 10-60 | 50-180 | 40-120 | 25-100 | 20-80 | 70-220 | 40-160 | 30-120 | 30-100 | 150-300 | 80-220 | 30-140 | 40-120 | 150-300 | 80-220 | 30-140 | 40-120 | 150-300 | 80-220 | 30-140 | 40-120 |

| Product Max. Weight | g | ||||||||||||||||||||||||||||||||

| EXTRUDER | |||||||||||||||||||||||||||||||||

| Screw Diameter | mm | 45 | 55 | 65 | 75 | 90 | 100 | 110 | 120 | ||||||||||||||||||||||||

| L / D | 26:1 | 26:1 | 26:1 | 26:1 | 28:1 | 28:1 | 28:1 | 30:1 | |||||||||||||||||||||||||

| Screw-speed Range (PE/PP) | RPM | 20-70 | 20-70 | 20-70 | 20-70 | 20-65 | 20-60 | 20-60 | 20-60 | ||||||||||||||||||||||||

| Induction Motor + Inverter (PE/PVC) | HP | 15 (20) | 20 (25) | 25 (30) | 40 | 60 (75) | 100 | 125 | 150 | ||||||||||||||||||||||||

| Max. Extruding Output/Per Hour | kgs | 30 (40) | 40 (50) | 50 (60) | 80 | 120 (150) | 200 | 250 | 300 | ||||||||||||||||||||||||

| Barrel Heating Zone | zone | 3 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | ||||||||||||||||||||||||

| Barrel Heating Capacity | kw | 5 | 8.1 | 10.4 | 15.8 | 22.8 | 23.8 | 27.4 | 27.4 | ||||||||||||||||||||||||

| DIE HEAD | |||||||||||||||||||||||||||||||||

| Twin Cavity Center Distance | mm | x | 100 | 85 | 80 | x | 100 | 85 | 80 | x | 120 | 100 | 85 | x | 140 | 120 | 100 | x | 180 | 140 | 120 | x | 250 | 160 | 140 | x | 250 | 160 | 140 | x | 250 | 160 | 140 |

| Heating Zone | zone | 2 | 3 | 5 | 8 | 3 | 3 | 5 | 8 | 3 | 3 | 5 | 8 | 5 | 4 | 4 | 7 | 5 | 6 | 5 | 7 | 5 | 7 | 7 | 7 | 5 | 7 | 7 | 7 | 5 | 7 | 7 | 7 |

| Heating Capacity | kw | 2.4 | 3.6 | 5 | 9.3 | 3.3 | 4 | 5 | 9.3 | 5.6 | 4.2 | 5 | 9.3 | 8.5 | 6.7 | 9 | 10.6 | 18.5 | 9.9 | 9.2 | 14.9 | 18.5 | 16.3 | 12.2 | 16.4 | 18.5 | 16.3 | 12.2 | 16.4 | 18.5 | 16.3 | 12.2 | 16.4 |

| MOLD PLATEN | |||||||||||||||||||||||||||||||||

| Clamping Force | Ton | 6.5 | 6.5 | 6.5/10.5 | 10.5/15.5(Toggle) | 15.5/18 | 18/21.5 | 18/21.5 | 21.5 | ||||||||||||||||||||||||

| Max. Opening Stroke | mm | 330 | 330 | 410 | 550 | 550/660 | 550/660/900 | 550/660/900 | 660/900 | ||||||||||||||||||||||||

| Min. Claming Stroke | mm | 80 | 80 | 140 | 185 | 185/220 | 185/220/300 | 185/220/300 | 220/300 | ||||||||||||||||||||||||

| Platen Size (WxH) | mm | 250x290 | 320x275 | 250x290 | 320x275 | 350x410 | 350x340 | 460x430/460x485(Toggle) | 520x485 | 600x485/600x660 | 600x485/600x660 | 600x485/600x660 | |||||||||||||||||||||

| Carriage Stroke | mm | ∅40x320 | ∅40x410 | ∅40x320 | ∅40x410 | ∅40x450 | ∅40x450 | ∅50x520 | ∅50x580 | ∅50x720 | ∅50x720 | ∅50x720 | |||||||||||||||||||||

| HYDRAULIC SYSTEM | |||||||||||||||||||||||||||||||||

| Pump Motor | HP | 20 | 20 | 30 | 30 | 30/40 | 40 | 40 | 40 | ||||||||||||||||||||||||

| Pump Pressure | kg/cm² | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||||||||

| Air Pressure | kg/cm² | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | ||||||||||||||||||||||||

| Air Volume | NL/Min | 500 | 500 | 600 | 900 | 1500 | 1500 | 1500 | 1500 | ||||||||||||||||||||||||

| Oil Tank Capacity | gallon | 100 | 100 | 100 | 100 | 100 | 107 | 107 | 107 | ||||||||||||||||||||||||

| Total Power Consumption | kw | 35.2 | 36.4 | 37.8 | 42.1 | 42.9 | 43.6 | 44.6 | 48.9 | 58.8 | 57.4 | 58.2 | 62.5 | 78.3 | 76.5 | 78.8 | 80.4 | 120.9 | 123.2 | 115.2 | 118.9 | 148.8 | 146.6 | 142.5 | 146.7 | 152.2 | 150 | 145.9 | 150.1 | 171 | 168.8 | 164.7 | 168.9 |

| Average Power Consumption | kw | 17.6 | 18.2 | 18.9 | 21.05 | 21.45 | 21.8 | 22.3 | 24.45 | 29.4 | 28.7 | 29.1 | 31.25 | 39.15 | 28.25 | 39.4 | 40.2 | 60.45 | 61.6 | 57.6 | 59.45 | 74.4 | 73.3 | 71.25 | 73.35 | 76.1 | 75 | 72.95 | 75.05 | 85.5 | 84.4 | 82.35 | 84.45 |

| Machine Weight | Ton | 6 | 6.1 | 6.2 | 6.3 | 7 | 7.1 | 7.2 | 7.3 | 9.2 | 9 | 9.1 | 9.3 | 11.1 | 11 | 11.2 | 11.3 | 13.2 | 13.1 | 13 | 13.3 | 14.2 | 14.1 | 14 | 14.3 | 14.2 | 14.1 | 14 | 14.3 | 14.4 | 14.3 | 14.2 | 14.5 |

PKCS3

PKCS4

* All specifications and designs are subject to change without notice.

Video

PK-110CTD Double Station Double Heads EBM Extrusion Blow Molding Machine

PK-110CTDV Double Station Double Head EBM Extrusion Blow Molding Machine

PK-100CT6 Twin Station Six Head Machine

PK-90CT8 Twin Station Eight Head Machine

PK-120CTD3L 3 Layer Twin Station Double Head Machine for 10L

PK-110CT4V Twin Station Four Head with View Stripe Machine for 1L

PK-100CT43LV 3 Layer Twin Station Four Head with View Stripe Machine for 1L

PK-110CTD Twin Station Double Head Machine for 5L

PK-120CTS Twin Station Single Head Machine for 20L

PK-90CT4 Twin Station Four Head Machine for 1L

PK-90CT4 Twin Station Four Head Machine for 1L/2L/3L

PK-80CTDV-HB Hybrid Twin Station Double Head with View Stripe Machine for 2L

PK 95CTS Twin Station Single Head EBM Extrusion Blow Molding Machine For PE 4 gallon Water Bottle