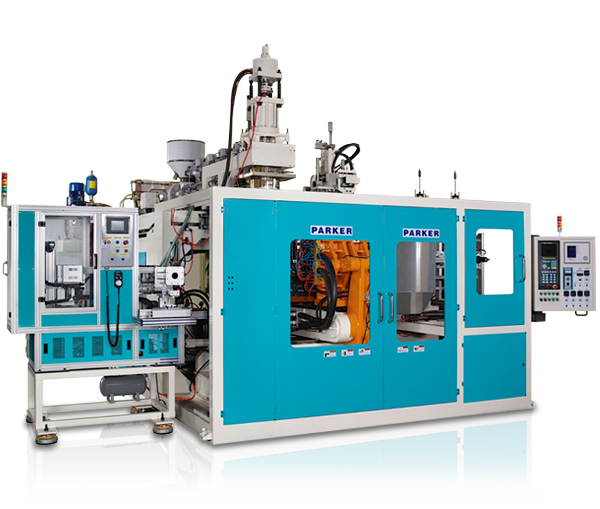

Accumulator Blow Molding Machine

PK-CSI series

- Single Station

- Single Head

- Production Volume:10L~30L

- Specialize for the PE/PP/PC/Nylon

- Clamping system:Toggle Type

- Driven Model: Hybrid servo motor drive system/ High performace hydraluic power saving system/Close loop proportional valve

- Support Parison controller/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML

Features & Application

Features

- HMI Touch Screen, Incorporating with PLC system (Optional Siemens/B&R Control) for easy maintenance.

- Blowing Unit/ Die Head movement for changing mold easily, as option.

- The plasticizing screw and barrel are precision machined from special nitrogen treated steel for maximum temperature and heat resistance.

- Water cooling technology controls feed zone temperature.

- Hydraulically controlled blow-pin with cooler circulation.

- The Accumulator Blow Molding Machine is especially suited to molding large volume capacity containers. (ex. Tool Box, Jerry cans, Water tanks, etc.), range from 10 to 35 litres.

Application

Jerry Can

Jerry Can

Jerry Can

Jerry Can

Bucket

Tool Kit

Bucket

Tool Kit

Specification

| MODEL | UNIT |

PK75I

|

PK100TSI

|

PK90I

|

PK90I-P

|

PK100I

|

PK100I-P

|

PK110LI

|

PK125I

|

|---|---|---|---|---|---|---|---|---|---|

| Material To Be Used | PE | PE | PE | PE | PE | PE | PE | PE | |

| PRODUCT | Marlex-571 | Marlex-571 | |||||||

| Product Volume (Min/Max) | Liter | 12-30 | 12-30 | 15-60 | 15-60 | 40-100 | 40-150 | 120-220 | |

| Product Dia. (Min/Max) | mm | 150-330 | 150-300 | 150-430 | 150-330 | 200-600 | 150-400 | 200-600 | 250-700 |

| EXTRUDER | |||||||||

| Screw Diameter | mm | 75 | 100 | 90 | 90 | 100 | 100 | 110 | 125 |

| L/D | 1:28 | 1:30 | 1:28 | 1:28 | 1:30 | 1:30 | 1:30 | 1:30 | |

| Screw-speed Range | RPM | 15-65 | 15-65 | 15-65 | 15-65 | 15-60 | 15-60 | 15-60 | 15-55 |

| Induction Motor+Inverter | HP | 50 | 100 | 60 | 75 | 100 | 100 | 125 | 150 |

| Max. Extruding Output/ Per Hour | kgs | 115 | 230 | 132 | 172 | 220 | 200 | 250 | 300 |

| Barrel Heating Zone | zone | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 7 |

| Barrel Heating Capacity | kw | 12 | 26.3 | 22.8 | 22.8 | 30.8 | 30.8 | 36.2 | 38.5 |

| DIE HEAD (ACCUMULATIVE TYPE) | |||||||||

| Heating Zone | zone | 4 | 4 | 4 | 4 | 6 | 9 | 9 | 9 |

| Heating Capacity | kw | 16.1 18.1 | 16.1 18.1 | 28 32 | 28 32 | 45 50 | 58 65 | 58 65 | 72 80 |

| Accumulative Capacity (Max.) | kgs/L | 2.3/3L 3/4L | 2.3/3L 3/4L | 4.3/5.8L 5.8/7.7L | 4.3/5.8L 5.8/7.7L | 8.6/11.4L 10.7/14.3L | 14.6/19.5L 17.5/23.4L | 14.6/19.5L 17.5/23.4L | 20.8/27.7L 25/33.3L |

| Outer Die Nozzle (Max.) | mm | 200 | 200 | 250 | 250 | 300 | 350 | 350 | 400 |

| Parison Thickness Controller | One Stage Hydraulic Controller | ||||||||

| Motor of Parison Thickness Controller | HP | 5 | 5 | 5 | 5 | 7.5 | 10 | 10 | 10 |

| MOLD PLATEN | |||||||||

| Max. Opening Stroke | mm | 1000 | 900 | 1300(1500) | 1000 | 1800 | 1200 | 1800 | 2000 |

| Min. Clamping Stroke | mm | 300 | 350 | 300(500) | 300 | 600 | 400 | 600 | 600 |

| Mold Thickness (Min / Max) | mm | 300-500 | 350-500 | 500-800 | 300-500 | 600-1000 | 400-600 | 600-100 | 600-1200 |

| Mold Dimension (W×H) | mm | 700×700 | 700×800 | 850×950 | 850×950 | 1000×1400 | 1400×1400 | 1400×1400 | 1400×1400 |

| HYDRAULIC SYSTEM | |||||||||

| Pump Motor | HP | 40 | 50 | 50 | 60 | 60 | 75 | 60 | 75 |

| Pump Pressure | kg/cm² | 140 | 140 | 140 | 140 | 140 | 140 | 180 | 140 |

| Mold Thickness Force | Ton | 22 | 22 | 35 | 56 | 45 | 70 | 56 | 70 |

| Oil Tank Capacity | gallon | 163 | 171.2 | 291 | 291 | 291 | 291 | 300 | 350 |

| Total Power Consumption | kw | 101.4 | 160.8 | 141.2 | 159.8 | 201.4 | 223.8 | 240.6 | 286.8 |

| Average Power Consumption | kw | 50.7 | 80.4 | 70.6 | 79.9 | 100.7 | 111.9 | 120.3 | 143.4 |

| Machine Weight | Ton | 9 | 18 | 9.5 | 10.5 | 12 | 11 | 16 | 18 |

* All specifications and designs are subject to change without notice.